It facilitates the achievement of the specified pace in machine cutting. Organizations in China and Taiwan are primary the race in the business. One of them is Accutex Systems Co. Ltd., from Taiwan that keeps a great popularity in the industry. Accutex Systems are manufactures of quality precision CNC equipment resources, CNC line cutting products form submarines, eliminating form cutting products, EDM products, cord EDM machining, cord cut EDM and CNC machines. It’s global ship markets with annual revenue of $ 2,000,000. The company favors USD whilst the currency in transactions.

Oscar EDM Organization Ltd is yet another primary organization from Taiwan that specializes in the production of EDM positioning models, EDM machining, line EDM machining, wire cut EDM, electrical release machines, CNC EDM, CNC cable EDM equipment and ignite erosion. Equally Ocean Techologies Co., Ltd is still another Taiwan organization with global exports in Line EDM. Sea Techologies is also popular for products in ceramic information, electrode tubes, instrument tools and spare parts.

Shenzhen Combined Industry Co., Ltd is one of major makers in cord EDM from China. The company manufactures CNC equipment & gear, including milling machinery, electrical launch machines, main equipment, grinders, counter grifers, move mills and EDM machines. Ocean Techologies in addition has acquired an ISO 9001: 2000 quality management global typical in 2003. Primarily all Wire EDM producers choose USD as currency and produce deliveries in respect with the FOB trade terms. The climbing demand of cord EDM and the raising number of producers has developed a healthy opposition, that has triggered production of better Cord EDM machines at low prices.

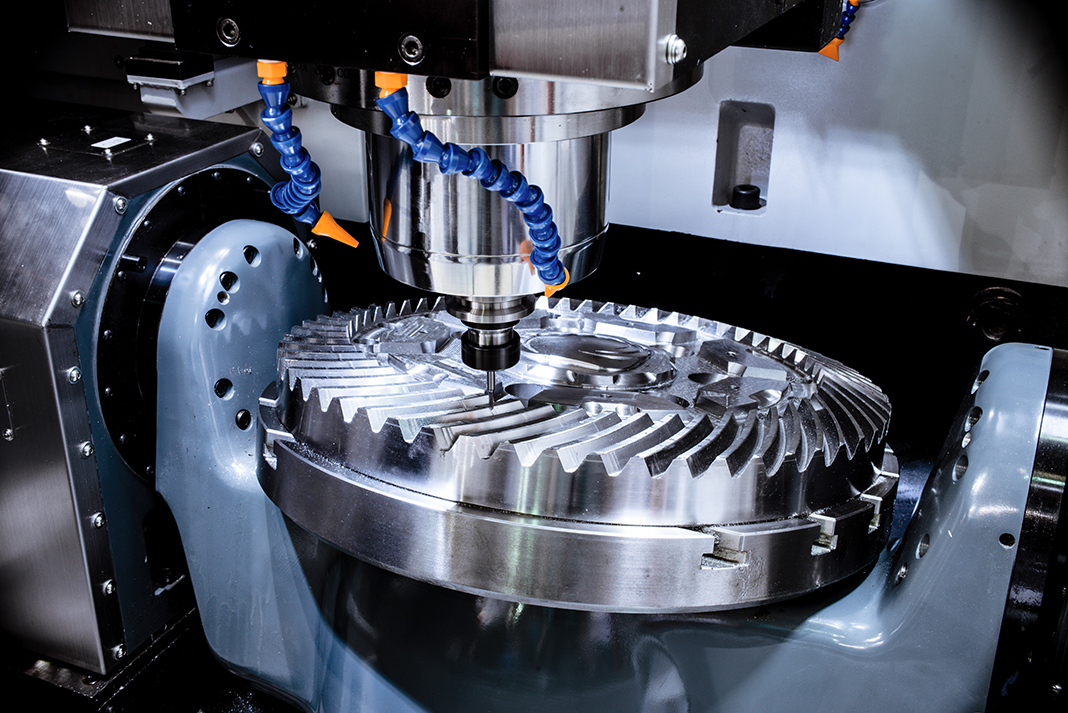

Line EDM solutions are not precisely new technology. The concept was originally discovered in the 1770’s by an British Scientist. It was not before 1970’s that EDM was commercially created, and in the 1980’s began to be distributed and applied through the world of equipment shops. Line EDM (Electrical Release Machining) is an electro thermal manufacturing procedure that eliminates metal in an exceedingly precise fashion by harnessing the warmth of an electric spark. Precision line (typically brass) is provided constantly from the spool through accuracy diamond books, one above and one under the work piece.

Since the cable is provided it’s empowered with electricity. The task bit to be machined, which must certanly be a conductive product, is grounded. The EDM machine techniques the cord (or the desk holding the work piece) in the trail that will be cut. While the cable nearly details the work bit, sparks begin to leap between the cord and function bit in an incredibly quickly, very managed manner. The sparks are microscopic and each spark eliminates a very microscopic piece of material.

Countless sparks per 2nd are continually removing product so that the line is apparently chopping through the task piece substance, leaving a difference or cut way behind it somewhat bigger compared to cord and in whatsoever path the line is set to undertake the work bit material. Dielectric water is provided continually within the wire and into the distance which cools and eliminates out the microscopic dissolved particles. The applied cable, which seems microscopically pitted, is taken up on a spool or sliced in to small pieces to be bought to a metal recycling facility.

The most common wire measurement utilized in EDM is.010″ diameter. The sparks themselves really use up place, inducing the curf or reduce of the cord to be bigger compared to the wire itself. A.010″ size wire might leave a reduce everywhere from.0106 to.014 broad, depending on the number of power applied to make the cut. The more power applied to make the cut, the quicker the cable travels, and the less accurate the cut route is.

Organizations providing line EDM solutions have a variety of equipment and possibilities to choose from. Mitsubishi, Agie, Charmilles, and Sodik are typical significant models of cable EDM machines. Several devices may run multiple cord measurements ranging from.0012″ dimension to.012″ diameter. Small wire dimensions let companies to accomplish micro machining and really small and complex parts. Line EDM is effective at producing a wide range of area finishes. At the rough end of the degree the completes start about 250 Ra microinch ( μ” ) and by usage of numerous cut passes can get down seriously to 4 Ra microinch ( μ” ). Many EDM devices can tip the cable, letting them make parts that have a tapered shape.